The Duty of Foam Control in Enhancing Item Quality and Effectiveness

Foam control is an often-overlooked yet essential element in the quest of product high quality and functional performance across varied markets. This conversation will explore the diverse influence of foam on both product honesty and production procedures, increasing necessary inquiries regarding the techniques that can be utilized to optimize foam control.

Recognizing Foam Formation

Foam formation is an intricate sensation that can dramatically influence product quality and functional efficiency across various markets. Comprehending these variables is critical for managing foam properly.

The fluid's thickness and surface stress play pivotal roles in foam stability. Surfactants, for example, can lower surface stress, advertising bubble formation but likewise improving foam security, which can be troublesome in specific applications. Mechanical agitation, temperature level fluctuations, and the existence of impurities can aggravate foam generation, making it vital to check these facets throughout manufacturing procedures.

Industries such as food and drink, drugs, and chemical production have to be particularly alert pertaining to foam control. By grasping the hidden mechanisms of foam formation, organizations can apply targeted methods to mitigate its impacts, thus preserving operational efficiency and ensuring consistent product efficiency.

Effect on Product Quality

The existence of foam can significantly jeopardize item quality across different markets. In producing procedures such as food and drink, pharmaceuticals, and cosmetics, extreme foam can result in inconsistent item solutions. For example, in food production, foam might trap air, affecting structure and flavor, which can ultimately change customer assumption and contentment.

Furthermore, foam can hinder the uniformity of coverings and paints, leading to issues like bubbles and unequal surfaces. In pharmaceutical applications, foam can hinder the accurate application of fluid medications, potentially influencing restorative efficacy and client safety and security. These top quality concerns not just decrease the end product's charm but can additionally bring about costly recalls and damage to brand name reputation.

Additionally, the presence of foam can make complex top quality control steps, making it challenging to accomplish accurate dimensions and constant outcomes. Reliable foam control not just alleviates these dangers yet also boosts general item top quality by making sure that formulas meet rigorous market standards. By spending in foam control strategies, companies can guard their products, boost consumer fulfillment, and keep an one-upmanship in the market.

Operational Challenges From Foam

Efficient operations in numerous markets can be significantly interfered with by the existence of foam, which presents several challenges throughout production procedures. Foam can impede mixing and response times, hampering the performance of chemical procedures. In industries such as food and beverage, foam formation can result in inaccurate fill levels, resulting in item waste and disparities in product packaging.

In environments where health is vital, such as pharmaceuticals and food handling, foam can make complex cleaning methods, producing concealed storage tanks for impurities. This not only elevates top quality worries however likewise can cause compliance problems with governing criteria.

In addition, the mental influence on drivers can not be neglected; extreme foam can produce a disorderly job setting, resulting in lowered spirits and efficiency. In summary, dealing with the operational challenges posed by foam is critical to preserving effectiveness and product top quality in different industries.

Techniques for Efficient Foam Control

Exactly how can markets successfully minimize the obstacles presented by foam? Efficient foam control approaches are vital for improving item high quality and functional performance. One main strategy is using defoamers, which are chemical agents developed to get rid of or lower foam formation. Picking the suitable defoamer needs a comprehensive understanding of the specific i thought about this procedure problems and the materials included.

In addition to chemical services, process optimization plays a crucial duty in foam administration. Industries can evaluate and change criteria such as blending temperature level, speed, and stress to minimize foam generation. Carrying out devices modifications, like setting up foam-breaking gadgets or adjusting container design, can even more help in reducing foam degrees.

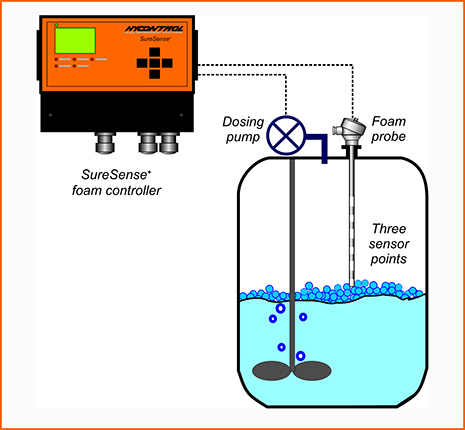

Routine surveillance and evaluation of foam actions within manufacturing processes are also important. Utilizing sophisticated sensing units and analytics can supply real-time data, permitting timely treatments and changes. Personnel training is equally essential; making certain that employees are well-informed about foam characteristics and control techniques can result in positive foam management.

Instance Researches and Sector Applications

While numerous industries deal with unique obstacles connected to foam control, case research studies reveal that customized techniques can dramatically boost both product quality and operational efficiency. In the pharmaceutical sector, as an example, a leading supplier applied a personalized foam control method that minimized foam development during fermentation procedures. This advancement not just enhanced return by 15% yet likewise decreased contamination threats, making certain greater product integrity.

In a similar way, in the food and drink industry, a significant dairy producer challenged too much foam during pasteurization - Foam Control. By presenting a specialized antifoam representative, they lowered handling time by 20%, which straight translated to raised throughput and decreased power intake. The application of foam control determines ensured regular product structure and preference, enhancing brand loyalty

In the chemical production sector, a study highlighted the effective application of foam control in wastewater therapy procedures. The implementation of a real-time surveillance system allowed operators to readjust antifoam dose dynamically, bring about a 30% decrease in chemical use and improved effluent high quality.

These study highlight the diverse applications of foam control throughout markets, stressing its important role in boosting product top quality and operational efficiency.

Final Thought

In final thought, effective foam control is important to boosting product quality and functional performance across numerous industries. Ultimately, prioritizing foam control adds to improved performance, securing brand name reputation, and increasing client satisfaction, highlighting its importance in top quality assurance within producing processes.

Foam control is an often-overlooked yet vital component in the pursuit learn this here now of item top quality and operational efficiency throughout diverse sectors. Personnel training is equally go right here important; ensuring that workers are well-informed concerning foam characteristics and control techniques can lead to proactive foam administration.

While lots of markets encounter one-of-a-kind challenges connected to foam control, instance researches expose that tailored strategies can significantly boost both product quality and operational effectiveness (Foam Control). In the pharmaceutical sector, for instance, a leading producer carried out a customized foam control approach that minimized foam development throughout fermentation procedures.In conclusion, efficient foam control is integral to improving item high quality and operational effectiveness across numerous industries